The Compressed Air Foam Fire Suppression System (CAFS) is an advanced fire suppression system that precisely mixes water, foam concentrate, and compressed air to produce high-performance foam, which is discharged through dedicated piping and discharge devices. By utilizing the energy of compressed air, the system generates foam with superior adhesion, coverage, and cooling efficiency, enabling highly effective fire suppression with significantly reduced water consumption.

CAFS is widely used in industrial, commercial, and special-hazard applications and is internationally recognized as a modern foam fire suppression solution characterized by high efficiency, water conservation, and rapid response, particularly suitable for projects with stringent requirements for fire suppression performance and water damage control.

The introduction of compressed air produces finer, more uniform foam with excellent adhesion, allowing rapid surface coverage, effective oxygen separation, and reduced risk of re-ignition.

Compared with traditional sprinkler systems or conventional foam systems, CAFS significantly reduces water usage, making it ideal for water-sensitive occupancies.

The foam provides both effective cooling and oxygen separation, enabling suppression of a wide range of fire types.

Driven by compressed air, the foam maintains consistent quality over long piping distances, ensuring fast delivery to the protected area.

The system can be integrated with fixed discharge devices, sprinklers, foam monitors, hose reels, or mobile equipment to accommodate various building layouts and process conditions.

With a mature system design and modular components, CAFS offers stable operation and simplified routine maintenance.

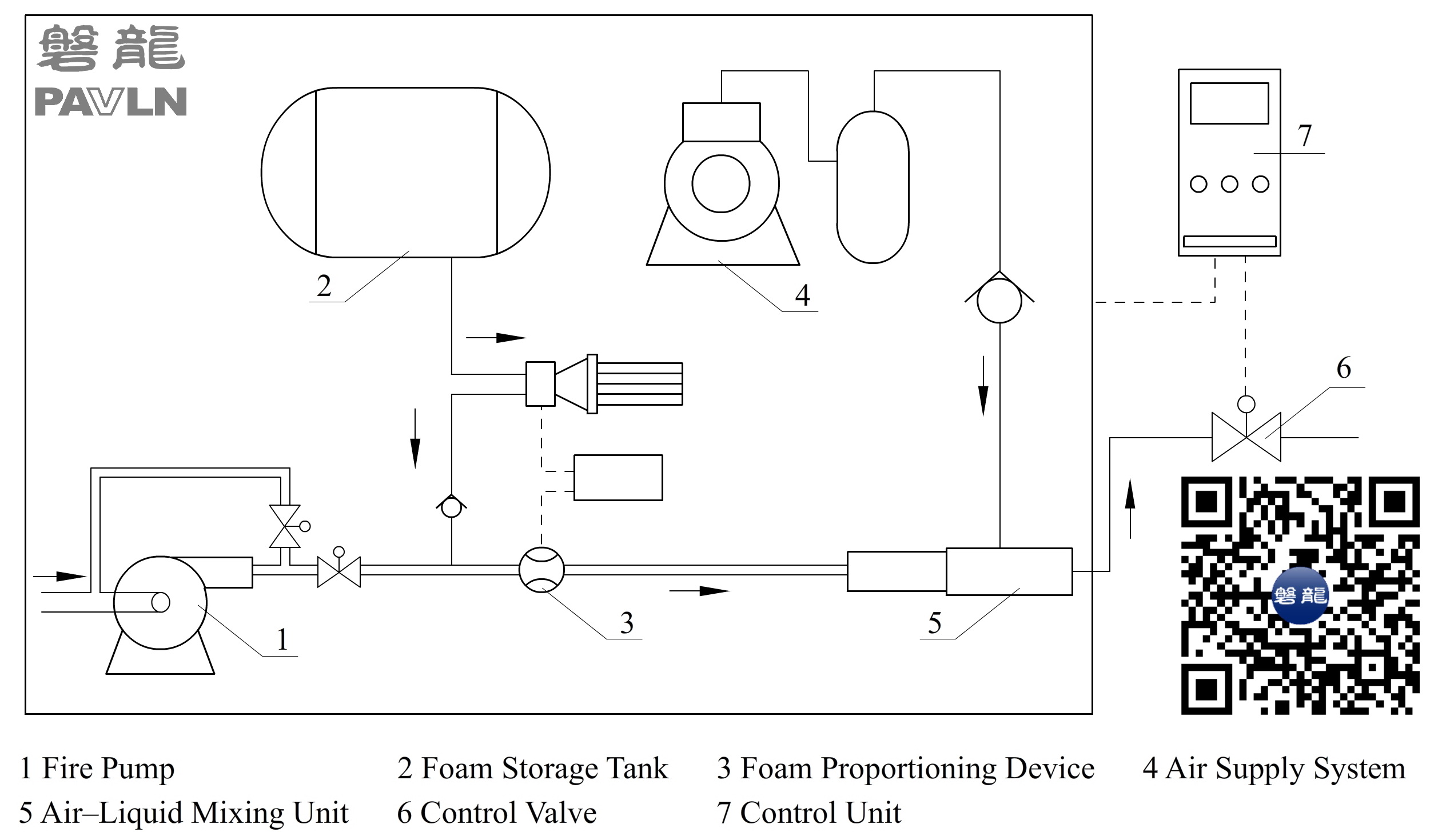

1. Upon system activation, the water supply delivers a stable water flow to the mixing unit.

2. Foam concentrate is proportionally injected into the water stream.

3. Compressed air is introduced into the mixing chamber, where it thoroughly blends with the foam solution to form compressed air foam.

4. The foam is conveyed through the piping network to discharge devices, rapidly covering and suppressing the fire.

5. After fire suppression, the system can be shut down promptly and returned to standby condition.

Model | CAFS400 | CAFS600 | CAFS1200 | CAFS2400 | CAFS3000 | CAFS4000 |

Foam solution flow rate(L/min) | 400 | 600 | 1200 | 2400 | 3000 | 4000 |

System Operating Pressure(MPa) | 1 | |||||

Foam Agent | AFFF | |||||

Air-to-Liquid Ratio | 7: 1 | |||||

Logistics and warehousing facilities, including high-rack storage

Underground parking garages and traffic tunnels

Oil-immersed transformers and oil-immersed reactors

Industrial plants and production workshops

Aircraft hangars and vehicle maintenance areas

Petrochemical facilities and flammable liquid hazards

Contact Us

If you are seeking a Compressed Air Foam Fire Suppression System (CAFS) with the following features:

High-quality foam with significantly enhanced fire suppression efficiency

Low water consumption with effective water damage control

Combined cooling and oxygen-separation fire suppression mechanisms

Long discharge distance and rapid system response

Compliance with foam fire protection and industrial fire safety requirements

Please contact our fire protection solutions team. We provide:

Risk assessment and system design for protected occupancies

Product selection, technical consultation, and code compliance support

Project pricing, supply, and engineering coordination

Installation guidance, commissioning support, and operation & maintenance training

We are committed to delivering efficient, water-saving, reliable, and internationally compliant advanced foam fire suppression solutions for customers worldwide.

Streamlined Steps to Obtain Your Custom Fire Protection Solution

Liaoyepo Road, Ningxiang High-tech Zone, Changsha City,Hunan Province, China

Your full-cycle fire protection partner. We handle everything from concept and installation to long-term safety assurance.

Other fire suppression systems you might be interested in

Fill out the form below and our team will contact you shortly

Get a free design consultation with our expert engineers.