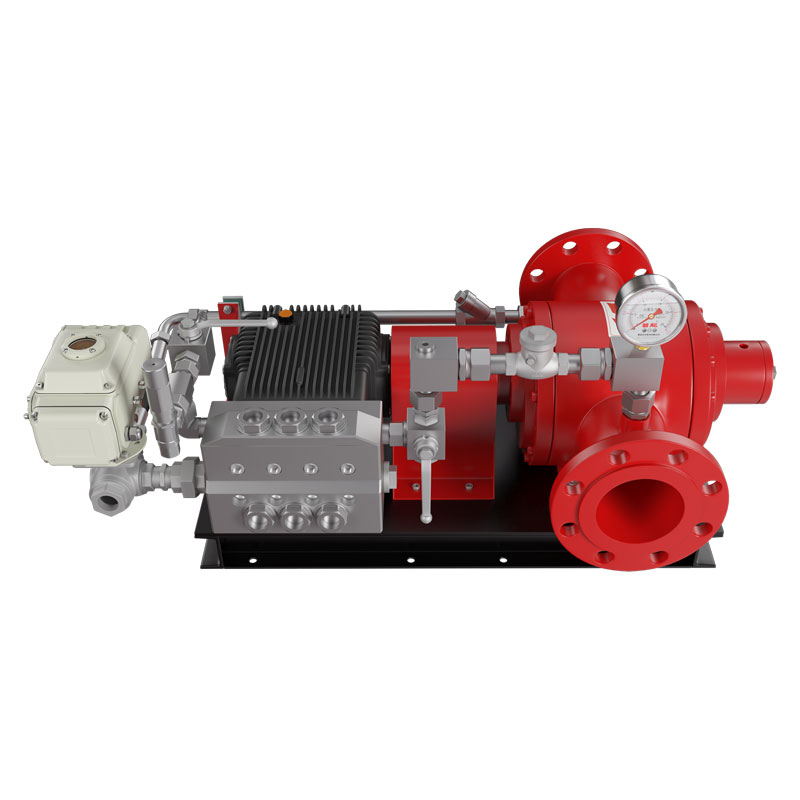

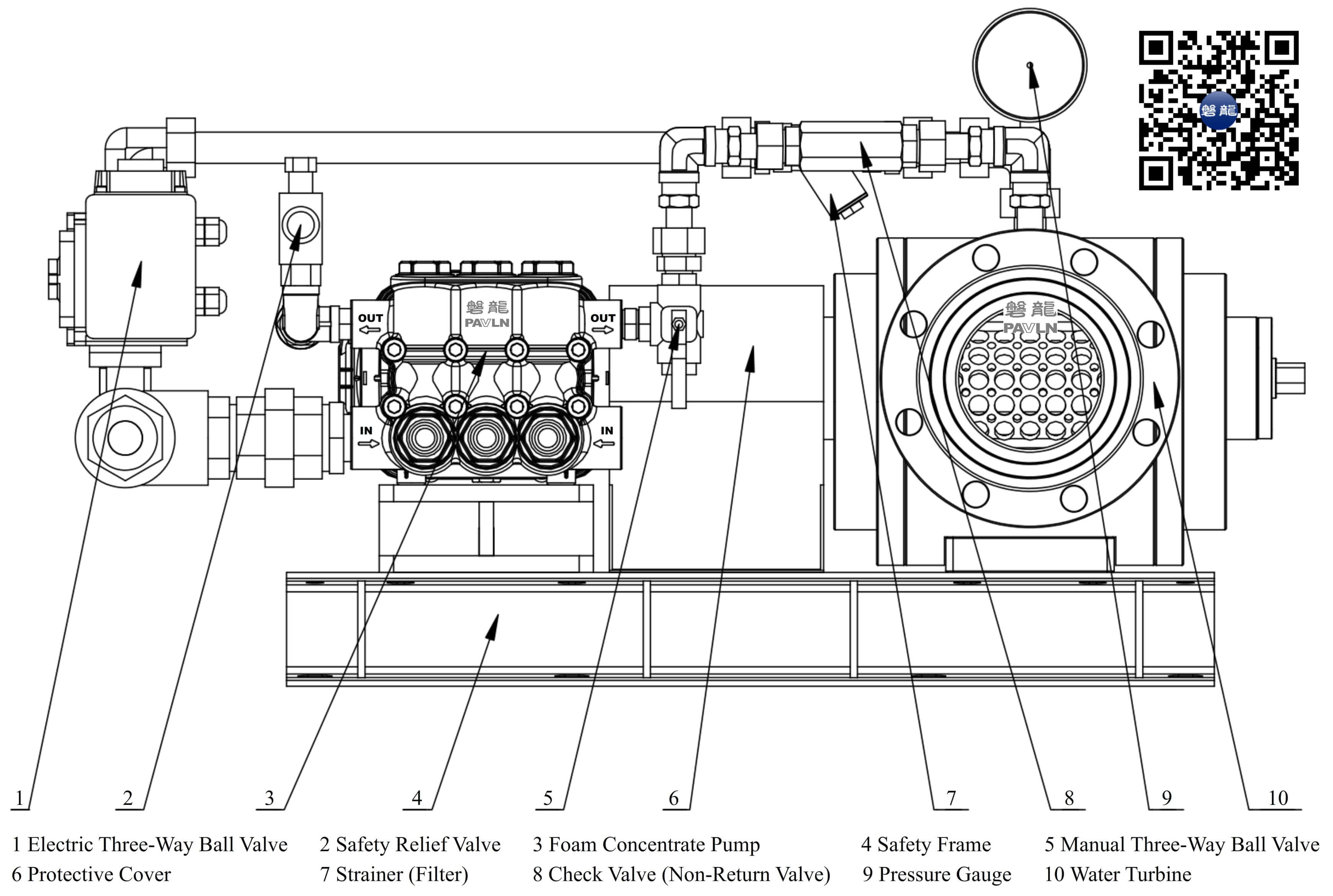

The Coupled Water-turbine Driven Pump Proportioning Equipment is a hydraulically driven foam proportioning device that requires no external power source. It is specifically designed for accurate proportioning and mixing of foam concentrate and water in foam fire suppression systems.

When fire water flows through the proportioner, the built-in water turbine is driven by the hydraulic energy of the water stream. Through a mechanical coupling, the turbine drives the foam concentrate pump, which draws foam concentrate from the storage tank and injects it under pressure into the water stream. This process ensures continuous, stable, and accurate foam proportioning over a wide range of flow conditions.

With its compact construction, fast response, and high proportioning accuracy, the mechanical pump proportioner is widely used in fixed foam fire suppression systems and foam spray systems, and is recognized internationally as a mature and reliable foam supply solution.

• No External Pow1. System Overview

The Coupled Water-turbine Driven Pump Proportioning Equipment is a hydraulically driven foam proportioning device that requires no external power source. It is specifically designed for accurate proportioning and mixing of foam concentrate and water in foam fire suppression systems.

When fire water flows through the proportioner, the built-in water turbine is driven by the hydraulic energy of the water stream. Through a mechanical coupling, the turbine drives the foam concentrate pump, which draws foam concentrate from the storage tank and injects it under pressure into the water stream. This process ensures continuous, stable, and accurate foam proportioning over a wide range of flow conditions.

With its compact construction, fast response, and high proportioning accuracy, the mechanical pump proportioner is widely used in fixed foam fire suppression systems and foam spray systems, and is recognized internationally as a mature and reliable foam supply solution.

• Required – Enhanced System Reliability

The system operates solely on hydraulic energy from the fire water supply and does not require electrical or pneumatic power, making it ideal for fire protection systems with extremely high reliability requirements.

• Stable Proportioning Over a Wide Flow Range

Through optimized matching of the water turbine and foam pump characteristics, the system maintains a consistent foam proportioning ratio across significant variations in water flow.

• Compact Design and Small Footprint

The integrated skid-mounted configuration facilitates transportation, installation, and maintenance, and is especially suitable for pump rooms or equipment rooms with limited space.

• Rapid Response and Instant Foam Supply

Foam concentrate delivery starts immediately with water flow, ensuring rapid formation of effective foam during the early stages of a fire.

• Proven Engineering Technology for Global Applications

The system is based on well-established technology and is easily integrated into internationally accepted foam system designs and standard engineering solutions.

The operating sequence of the Coupled Water-turbine Driven Pump Proportioning Equipment is as follows:

The fire protection system is activated and water enters the proportioning unit

The flowing water drives the internal water turbine

The turbine transmits mechanical power through a coupling to the foam concentrate pump

The foam pump draws foam concentrate from the foam storage tank

The foam concentrate is pressurized and injected into the fire water pipeline

Foam concentrate and water are mixed at the preset proportion to form a foam solution

The foam solution is delivered to discharge devices such as foam nozzles or foam generators for fire suppression

The entire process is fully automatic, requiring no manual intervention, and provides continuous and accurate foam proportioning.

Model Specification | PHB25/3-PAVLN | PHB40/3-PAVLN | PHB66/3-PAVLN | PHB100/3 -PAVLN | PHB135/3 -PAVLN | PHB170/3 -PAVLN | PHB250/3 -PAVLN |

Working Pressure (MPa) | 0.6~1.6 | 0.6~1.6 | 0.6~1.6 | 0.6~1.6 | 0.6~1.6 | 0.6~1.6 | 0.6~1.6 |

Fire Extinguishing Agent Type | AFFF | AFFF | AFFF | AFFF | AFFF | AFFF | AFFF |

Concentration | 3% | 3% | 3% | 3% | 3% | 3% | 3% |

Flow Range (L/s) | 3~25 | 4~40 | 6~66 | 4~100 | 7~135 | 7~170 | 12~250 |

Water Turbine Nominal Diameter | DN100 | DN100 | DN150 | DN200 | DN200 | DN200 | DN200 |

Coupled Water-turbine Driven Pump Proportioning Equipment are widely used in the following foam fire suppression applications:

Foam spray fire suppression systems

Fixed foam fire suppression systems

Foam-water sprinkler systems

Oil depots and tank farms

Petrochemical processing areas

Fuel-fired boiler rooms

Diesel or fuel-oil generator rooms

Aircraft hangars and maintenance facilities

They are particularly well suited for high-flow fire protection scenarios requiring continuous and stable foam delivery.

Take Action Now

Are you looking for a professional solution that addresses the critical challenges of foam fire protection systems?

Consistent foam proportioning for reliable discharge performance

No external power requirement, eliminating electrical or pneumatic failure risks

Compact footprint for installation in space-constrained facilities

High reliability and simple maintenance, reducing life-cycle costs

Proven technology suitable for international projects and global deployment

The Coupled Water-turbine Driven Pump Proportioning Equipment provides accurate, stable, and highly reliable foam proportioning at the core of your fire protection system.

Contact our international expert team to obtain a customized proportioning solution based on your specific operating conditions, flow requirements, and hazard classification, along with global engineering support and long-term service assurance.

Streamlined Steps to Obtain Your Custom Fire Protection Solution

Liaoyepo Road, Ningxiang High-tech Zone, Changsha City,Hunan Province, China

Your full-cycle fire protection partner. We handle everything from concept and installation to long-term safety assurance.

Other fire suppression systems you might be interested in

Fill out the form below and our team will contact you shortly

Get a free design consultation with our expert engineers.