The Kitchen Equipment Fire Suppression System (Electrically-Actuated Type) is a fixed automatic fire suppression system specifically designed for high fire-risk commercial kitchen environments. The system integrates heat-sensing detection elements with a solenoid actuation mechanism. When a fire occurs in kitchen equipment—such as deep fryers, cooking appliances, exhaust hoods, and exhaust ducts—the system is automatically or manually actuated to rapidly and precisely discharge a dedicated wet chemical extinguishing agent directly onto the fire source, achieving effective control and extinguishment of cooking oil and grease fires.

This system is highly effective in addressing high-temperature cooking oil fires commonly encountered in kitchens. It can be interlocked with fuel gas shutoff valves, electrical power shutoff, and ventilation systems, making it a mature and widely adopted fire protection solution for international commercial kitchens, restaurant chains, and food processing facilities.

Electrically Actuation with Fast and Reliable Response

The system uses a solenoid valve as the actuation device, providing rapid response and stable operation. It can be interconnected with a fire alarm control system for coordinated activation.

Dedicated Extinguishing Agent for Grease Fires

A wet chemical extinguishing agent specifically designed for commercial kitchens is used. The agent forms a soapy blanket through saponification on the surface of high-temperature cooking oils, rapidly cooling the fuel and preventing re-ignition, providing excellent suppression of Class K fires.

Dual Actuation: Automatic and Manual

The system supports both automatic actuation via heat detection and manual emergency actuation, ensuring operational safety under all conditions.

Multi-Point, Targeted Discharge Covering Critical Hazard Areas

Nozzles are strategically arranged to provide directed discharge to cooking appliances, deep fryers, exhaust hoods, and duct interiors, ensuring comprehensive protection of key fire risk locations.

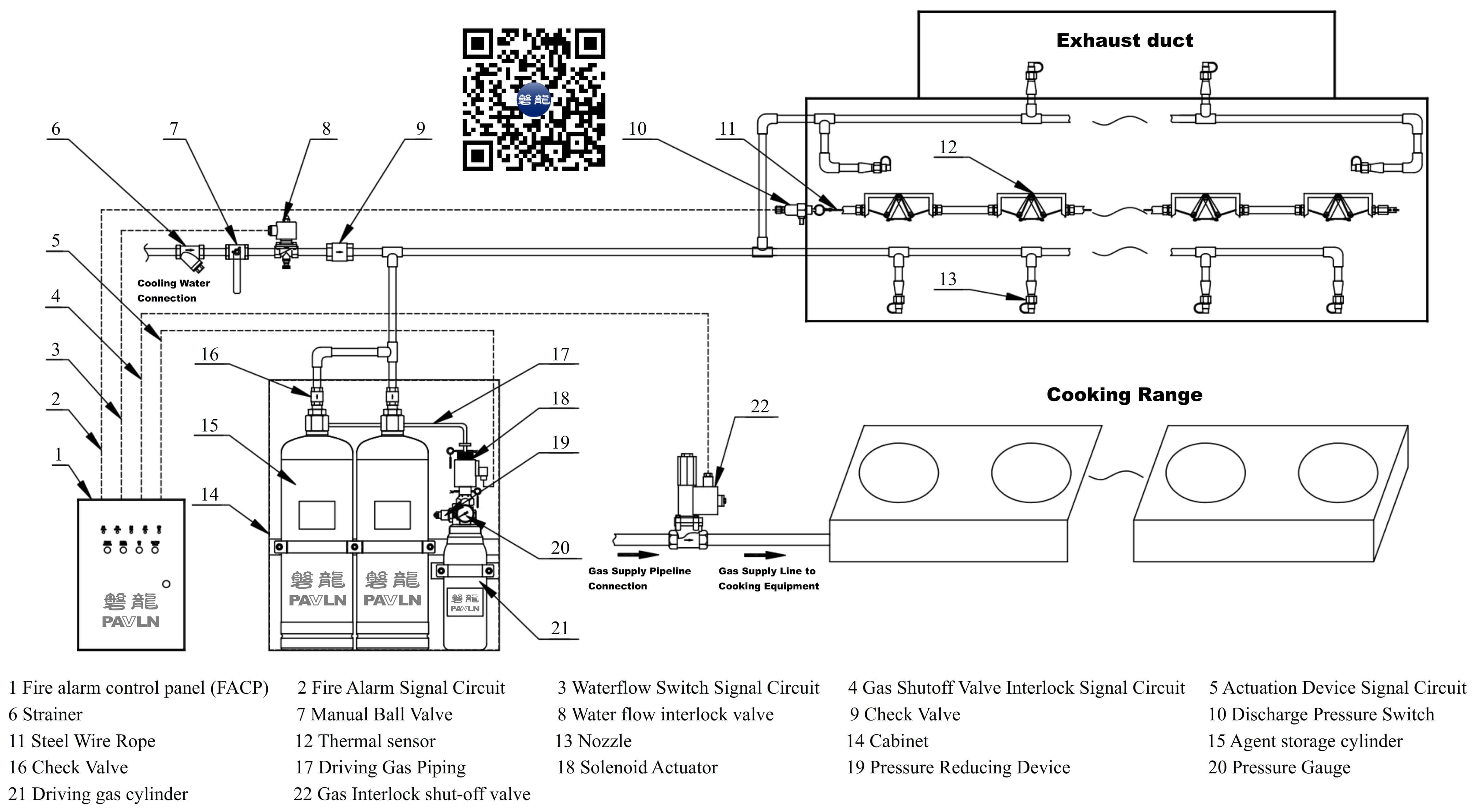

When a kitchen appliance (such as a fryer) catches fire and the temperature reaches the threshold set by the thermal sensor (e.g., a fusible link), the thermal device activates, triggering the wire release mechanism and initiating a fire signal:

A signal is sent to the fire alarm control panel(FACP) via the feedback device.

The FACP activates the audible and visual alarm and sends out interlock control commands.

Automatically shuts off the gas supply.

Shuts down ventilation and exhaust systems.

Enters a delay start phase (adjustable delay from 0 to 30 seconds) to ensure exhaust airflow ceases.

The solenoid actuator triggers the driving gas cylinder to release high-pressure nitrogen.

Nitrogen is depressurized and enters the agent storage cylinder, forcing the release of the suppression agent.

The agent is discharged through nozzles positioned above stoves, hoods, and ducts for uniform distribution and rapid extinguishing.

After discharge, the system transitions to the pressure release phase.

After agent discharge, the system activates the water flow interlock valve (optional delay configurable).

Under low-pressure conditions, cooling water flows through the same piping to cool high-temperature surfaces.

This effectively prevents reignition.

Model | CMDS10-1-PAVLN | CMDS20-2-PAVLN |

Activation Methods | Electric Actuation | |

Number of Agent Cylinders | 1 | 2 |

Agent Weight | 10kg | 20kg |

Number of Nozzles | 10 | 20 |

Agent | Wet Chemical Fire Extinguishing Agent (for Cooking Oil Fires) | |

Driver Gas Storage Pressure | 6MPa(20℃) | |

Driving Gas | Nitrogen | |

CFPA Power Supply | AC220V,50Hz | |

Operating Temperature of Heat Detector | 183℃ | |

Operating Ambient Temperature | 4 ℃ ~ 55 ℃ | |

Commercial catering kitchens (restaurants, hotels, chain food service operations)

Food processing plants and central kitchens

Staff canteens and large-scale catering facilities

Commercial frying areas, cooking zones, and exhaust systems

Kitchens in aviation, marine, and other special-use facilities

Contact Us

If you are seeking a kitchen fire suppression system with the following features:

Solenoid actuation with fast response and stable operation

Dedicated wet chemical agent for effective grease fire suppression

Dual automatic and manual actuation for enhanced safety

Multi-point discharge for full coverage of critical kitchen hazards

Interlocking with gas, electrical power, and exhaust systems to prevent re-ignition

Please contact our fire protection solutions team for:

Commercial kitchen fire risk assessment and system design

Product configuration, technical selection, and code compliance support

Project quotation, delivery, and technical services

Installation guidance, commissioning support, and operational training

We are committed to providing safe, efficient, and internationally compliant fire protection solutions for commercial kitchen applications worldwide.

Streamlined Steps to Obtain Your Custom Fire Protection Solution

Liaoyepo Road, Ningxiang High-tech Zone, Changsha City,Hunan Province, China

Your full-cycle fire protection partner. We handle everything from concept and installation to long-term safety assurance.

Other fire suppression systems you might be interested in

Fill out the form below and our team will contact you shortly

Get a free design consultation with our expert engineers.