The Oil Evacuation and Nitrogen Injection Extinguishing Equipment of Transformer is a specialized fire protection system designed specifically for the fire hazards associated with oil-immersed power transformers.

In the event of an internal fault or an incipient fire within the transformer, the system rapidly drains high-temperature transformer oil while simultaneously injecting inert nitrogen gas into the transformer tank, thereby quickly suppressing combustion, reducing explosion risk, and preventing fire escalation.

This system is widely applied in substations, power plants, and critical industrial facilities, and is recognized internationally within the power industry as a mature, reliable active fire suppression and explosion-prevention solution dedicated to oil-immersed transformers.

By rapidly removing the burning fuel (transformer oil) and injecting nitrogen to reduce oxygen concentration, the system suppresses fire development simultaneously from both the fuel source and combustion-supporting conditions.

The system significantly reduces internal tank pressure and temperature, minimizing the risk of explosion caused by oil vapor expansion or secondary combustion.

Engineered according to the structural characteristics of oil-immersed transformers, the system is suitable for large-capacity and high-voltage transformers requiring direct tank protection.

The system can be interlocked with transformer protection systems and fire detection systems, enabling automatic activation and rapid intervention during the early stage of a fire.

Nitrogen, an inert extinguishing medium, produces no chemical residue and has minimal impact on equipment and the environment.

A self-sealing nitrogen cylinder valve is employed; under normal operating conditions, the nitrogen injection piping remains unpressurized, significantly improving system safety.

A reliable mechanical interlock control mechanism ensures the correct operating sequence—oil drainage first, nitrogen injection second—preventing transformer tank overpressure.

The oil drainage device incorporates a dual safety locking design, preventing unintended oil discharge under normal conditions while ensuring rapid and reliable oil drainage during emergency activation.

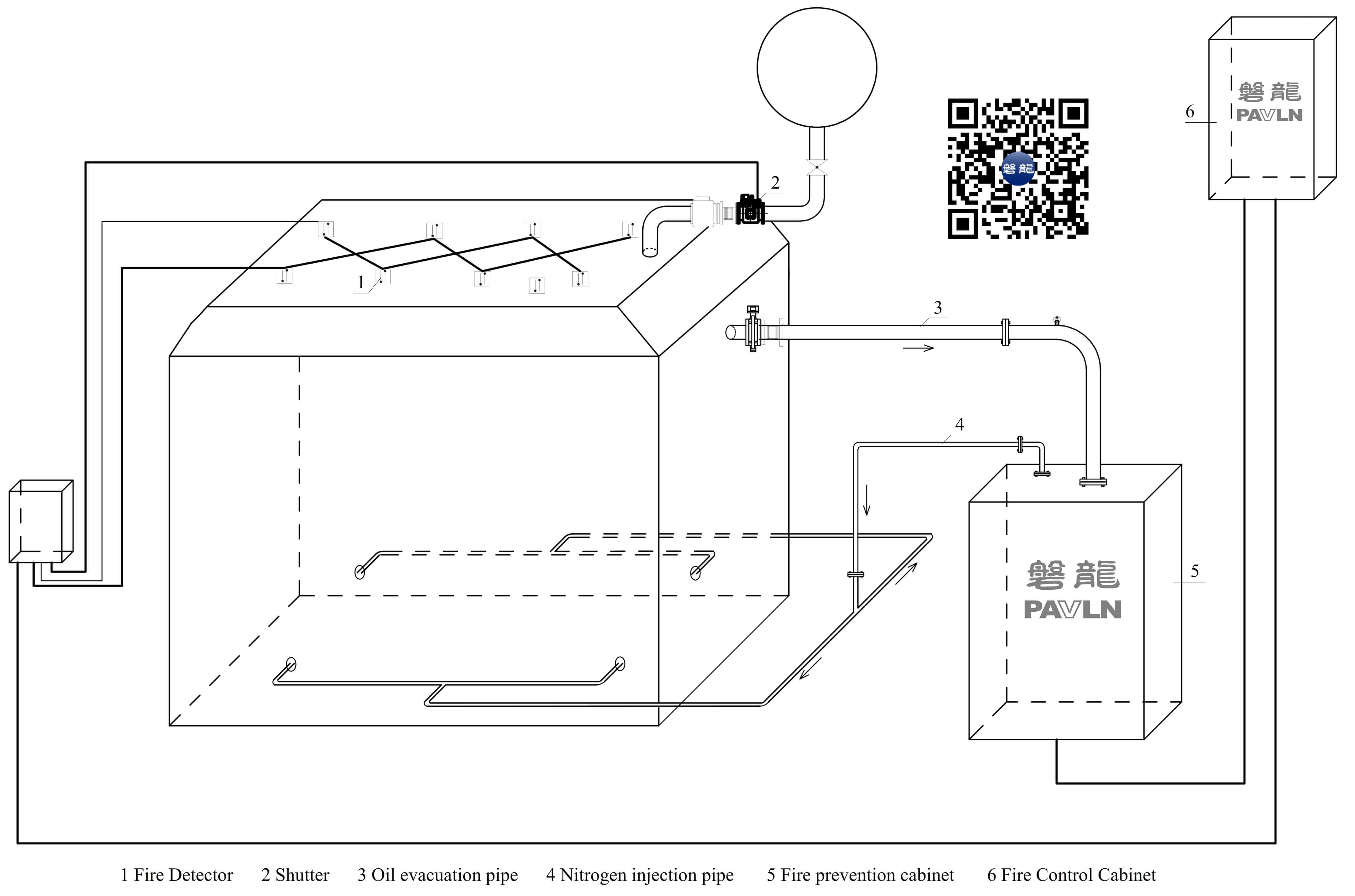

1. An internal fault or fire occurs within the transformer, and the protection system detects abnormal conditions.

2. Upon receiving an activation signal, the oil drainage and nitrogen injection fire suppression system automatically operates.

3. The oil drainage valve opens rapidly, discharging high-temperature transformer oil into an emergency oil pit or safe oil collection system.

4. Simultaneously, high-pressure nitrogen gas is injected into the transformer tank, reducing oxygen concentration and suppressing combustion.

5. The system continues to operate until the fire is effectively controlled, preventing re-ignition and explosion.

Operating Environment | Fire Control Cabinet Operating Ambient Temperature | 0℃~50℃ |

Control Cabinet Operating Ambient Temperature | -40℃~60℃ | |

Relative Humidity | Relative humidity not exceeding 85% at 40 ℃ | |

Power Supply | DC220V | |

Fire prevention cabinet | Nitrogen Cylinder Capacity | 1×80L |

Nitrogen Cylinder Storage Pressure | 8~15MPa | |

Activation Pressure of Nitrogen Cylinder Safety Relief Device | 21MPa | |

Nitrogen Pressure at Pressure Regulator Outlet | 0.6MPa | |

Flow Rate at Pressure Regulator Outlet | 60m3/h | |

Flow Rate at Flow Control Valve Outlet | >200L/min | |

Solenoid-Type Actuating Device Parameters | Operating Voltage: DC 220 V Actuating Force: 100 N | |

Fire Detector | Fusible Element | Fusible Alloy |

Actuation Temperature | 110℃士10℃ | |

Nitrogen Injection Piping | Operating Pressure | 1.6MPa |

Connection Pipe Diameter | DN25 | |

Oil Drainage Piping | DN125 | |

Oil-immersed transformers and oil-immersed reactors in transmission and distribution substations

Oil-immersed transformers and oil-immersed reactors in thermal power plants, hydropower plants, and nuclear power plants

Oil-immersed transformers and oil-immersed reactors serving industrial facilities

If you are seeking an Oil Evacuation and Nitrogen Injection Extinguishing Equipment of Transformer with the following features:

A dedicated fire suppression and explosion-prevention solution specifically designed for oil-immersed transformers

Coordinated oil drainage and nitrogen injection with high fire suppression efficiency

Automatic response with significantly reduced explosion and re-ignition risks

Compliance with power industry and fire protection safety design requirements

Please contact our fire protection solutions team. We provide:

Transformer fire risk assessment and system configuration recommendations

Technical solutions, code-compliance consultation, and design support

Product selection, engineering pricing, and project coordination services

Installation guidance, commissioning support, and operation & maintenance training

We are committed to delivering safe, reliable, and internationally compliant transformer-dedicated fire protection solutions for power and industrial clients worldwide.

Streamlined Steps to Obtain Your Custom Fire Protection Solution

Liaoyepo Road, Ningxiang High-tech Zone, Changsha City,Hunan Province, China

Your full-cycle fire protection partner. We handle everything from concept and installation to long-term safety assurance.

Other fire suppression systems you might be interested in

Fill out the form below and our team will contact you shortly

Get a free design consultation with our expert engineers.