The Special-Type Steel Fire Shutter with Water Mist System (Vertical Rolling Type) is a high-performance fire separation assembly that integrates a steel fire shutter with an automatic water mist cooling system.

During a fire event, the shutter descends vertically to form a physical fire barrier, while a continuous water mist layer is simultaneously discharged onto the shutter surface to provide cooling and protection, significantly enhancing the overall fire resistance and thermal insulation performance.

This type of special-type steel fire shutter with water mist protection is widely used in buildings with large openings, very high fire-resistance requirements, and long-term operational reliability demands. It is a proven, high-level fire compartmentation solution commonly adopted in large public buildings and critical protected areas.

1. Steel construction combined with water mist cooling for superior fire resistance

The shutter is constructed of high-strength steel, and the water mist system provides continuous surface cooling during a fire, effectively reducing thermal exposure and meeting special-type fire-resistance requirements.

2. Vertical rolling configuration with reliable compartmentation

The vertically descending shutter design is mature and reliable. Once fully deployed, it forms a continuous and stable fire barrier, suitable for standard and large opening applications.

3. Effective reduction of unexposed surface temperature rise

A uniform water mist cooling layer forms on the shutter surface, significantly reducing radiant heat transfer and improving safety in adjacent compartments.

4. Low water consumption with minimal water damage

The water mist cooling method requires substantially less water than conventional sprinkler systems, reducing water usage and minimizing secondary water damage.

5. Single-curtain design with reduced space requirements

A single curtain structure is used. Compared with special-type inorganic fire shutters employing double curtains, this design occupies less space.

6. Reliable smoke control performance

The steel curtain combined with sealed guide rails effectively limits smoke leakage while blocking flames, meeting smoke compartmentation design requirements.

7. System interlocking for safe and controlled operation

The system can be interlocked with the fire alarm system and sprinkler or water mist systems, ensuring automatic shutter descent and synchronized water mist activation during a fire.

Under normal conditions, the steel fire shutter is rolled up above the opening, and the water mist system remains on standby.

Upon fire detection, the fire alarm system issues an activation signal.

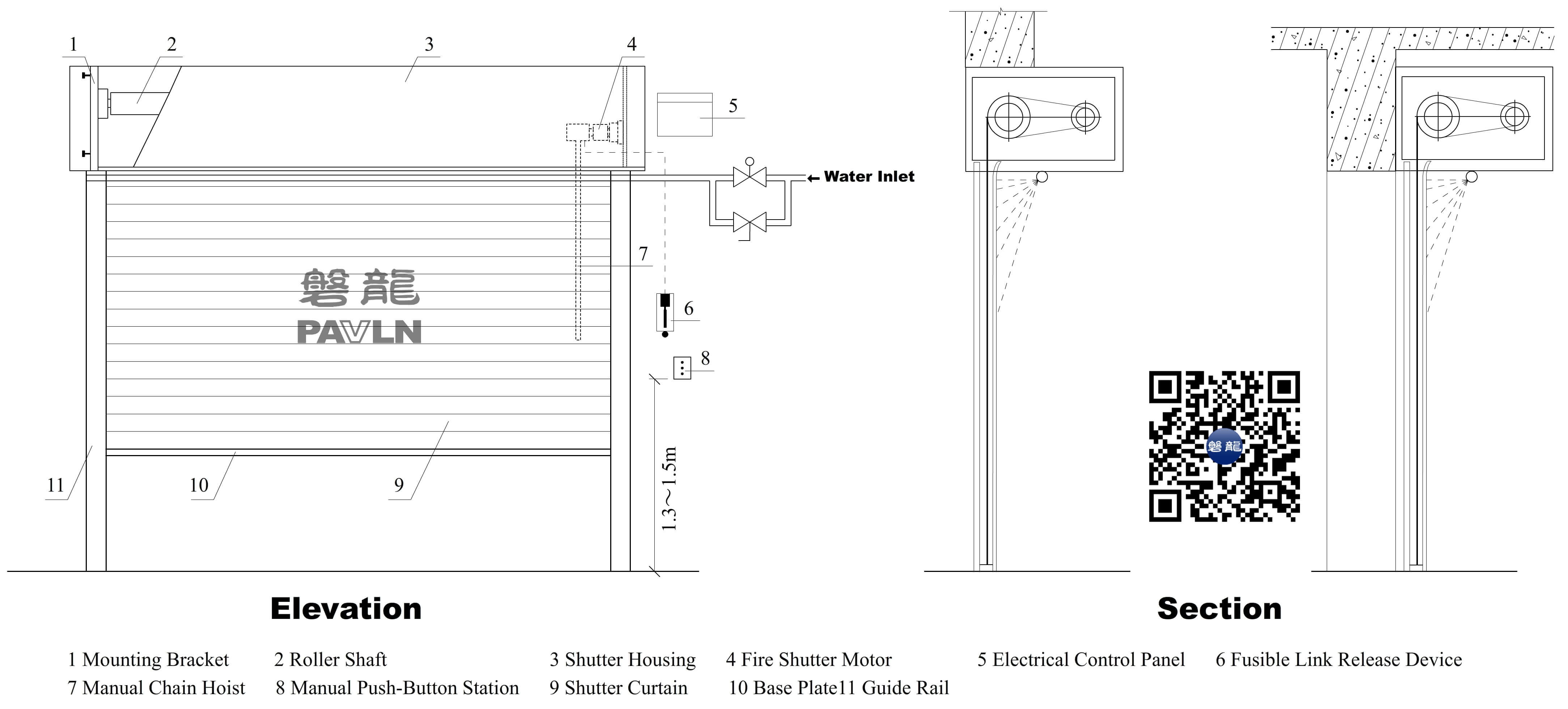

The fire shutter control unit is activated, and the shutter descends vertically along the guide rails to close the opening.

A temperature-activated release valve operates upon heat exposure, allowing water to flow through the spray piping and form a continuous water mist layer on the shutter surface for cooling and protection.

Throughout the fire event, the shutter and water mist system operate together to form a high-grade fire and smoke barrier.

Curtain material: Steel composite fire curtain

Fire resistance rating: Special-type fire resistance (integrity and insulation)

Operation mode: Automatic vertical descent

Water mist discharge mode: Continuous or interlocked discharge

Activation methods:

Automatic activation

Manual activation

Temperature-activated automatic descent

Mechanical emergency descent

Maximum opening size: Customized per project requirements

Water application density on curtain surface: 0.23 m³/(h·m²)

Fire compartments in large commercial complexes and shopping centers

Transportation hubs such as metro stations and airport terminals

Large-space buildings including exhibition centers, theaters, and stadiums

Industrial plants and logistics/warehousing centers

Building areas with extremely high requirements for fire resistance and compartmentation reliability

If you are seeking a Special-Type Steel Fire Shutter with Water Mist System (Vertical Rolling Type) featuring:

Steel construction combined with water mist cooling to meet special-type fire resistance requirements

Reliable vertical rolling fire compartmentation

Effective reduction of unexposed surface temperature rise

Low water consumption with minimal water damage

Reliable smoke control performance with water system interlocking

Compliance with international fire protection and fire compartmentation standards

Please contact our fire protection solutions team for:

Fire compartmentation and opening condition analysis

Product selection, technical consultation, and code compliance support

Project pricing, supply, and engineering coordination

Installation guidance, commissioning support, and maintenance training

We are committed to providing safe, reliable, and internationally compliant high-grade fire and smoke compartmentation solutions for global projects.

Streamlined Steps to Obtain Your Custom Fire Protection Solution

Liaoyepo Road, Ningxiang High-tech Zone, Changsha City,Hunan Province, China

Your full-cycle fire protection partner. We handle everything from concept and installation to long-term safety assurance.

Other fire suppression systems you might be interested in

Fill out the form below and our team will contact you shortly

Get a free design consultation with our expert engineers.